Designed to cut through the hardest rock, with unrivalled production rates and pumping power, Spartacus unlocks new areas of opportunity.

The vessel represents the pinnacle of more than 140 years of dredging expertise.

This is pure power with a soft spot for the environment

This is Spartacus.

Proceed

with power

Spartacus boasts unseen power levels, with a total installed capacity of 44,180 kW. This force gives Spartacus unbeatable production rates and its ability to cut hard soil is unrivalled. Projects that would not have been feasible before are now possible. Spartacus turns ambitious plans into realistic projects. With no exaggeration – the vessel is a game changer.

- A LADDER WITH HEAVYWEIGHT CAPABILITIES

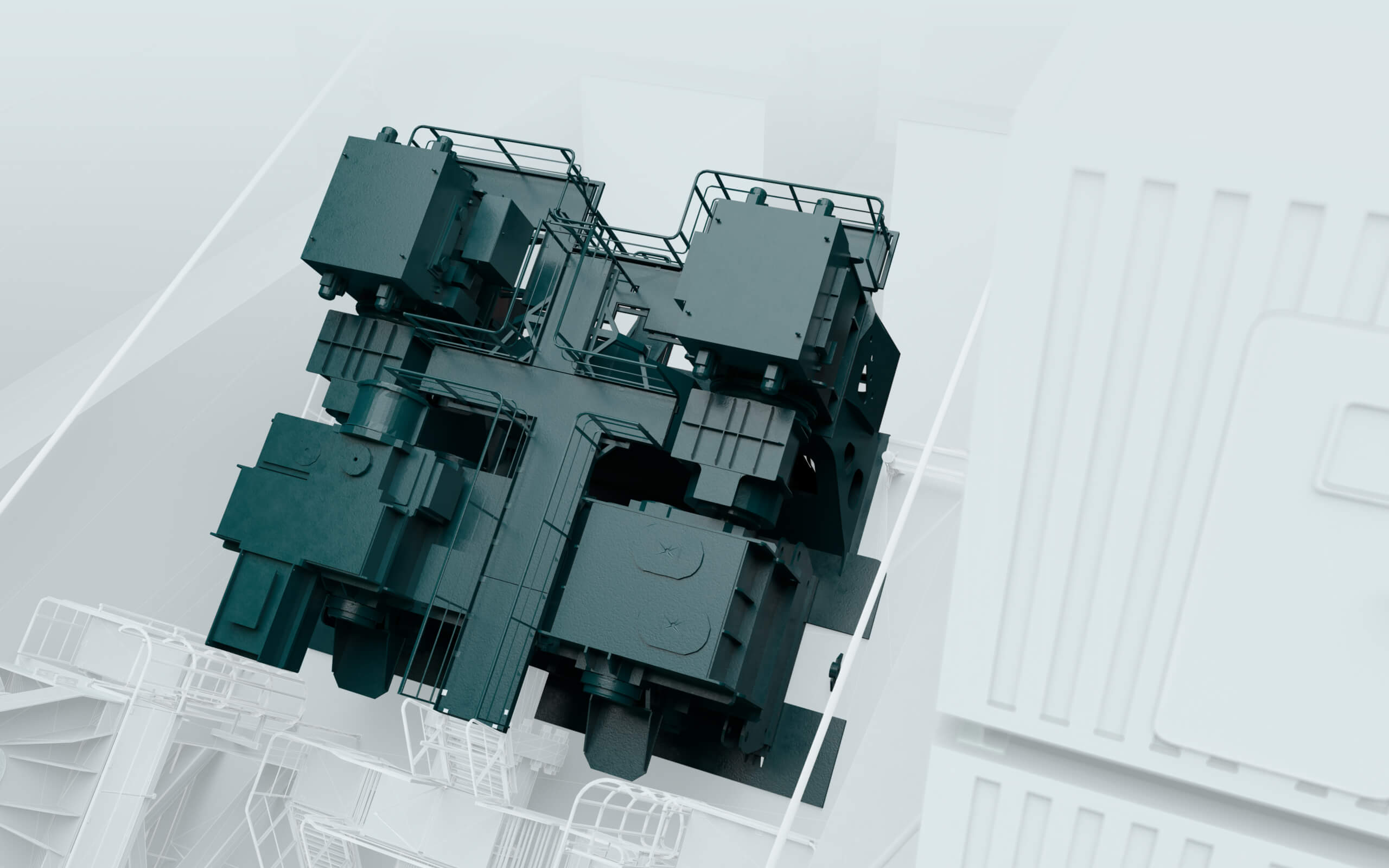

The more its ladder weighs, the more pressure a cutter suction dredger can apply. With a cutter ladder weighing a staggering 2,550 tonnes, Spartacus can dredge in depths of up to 45 metres and delivers superior uptime thanks to its resistance to vibrations. - NEW GENERATION CUTTER DRIVE

To make sure Spartacus can power the new cutterheads and heavyweight ladder, it can deliver an unprecedented power of 12,000 kW on the cutterhead. This is double the power of the current generation of mega cutter suction dredgers. The gearbox converting this power is the largest ever built. - EXTREME PUMPING POWER

Immense dredging power brings a huge amount of dredged materials. However, unloading materials through a booster station severely limits any cutter suction dredger’s autonomy. Not so with Spartacus as we have increased the vessel’s pumping power to 25.5 MW. Spartacus can operate autonomously and discharge dredged materials over more than 10 km. - CUTTERHEADS FOR EVERY CHALLENGE

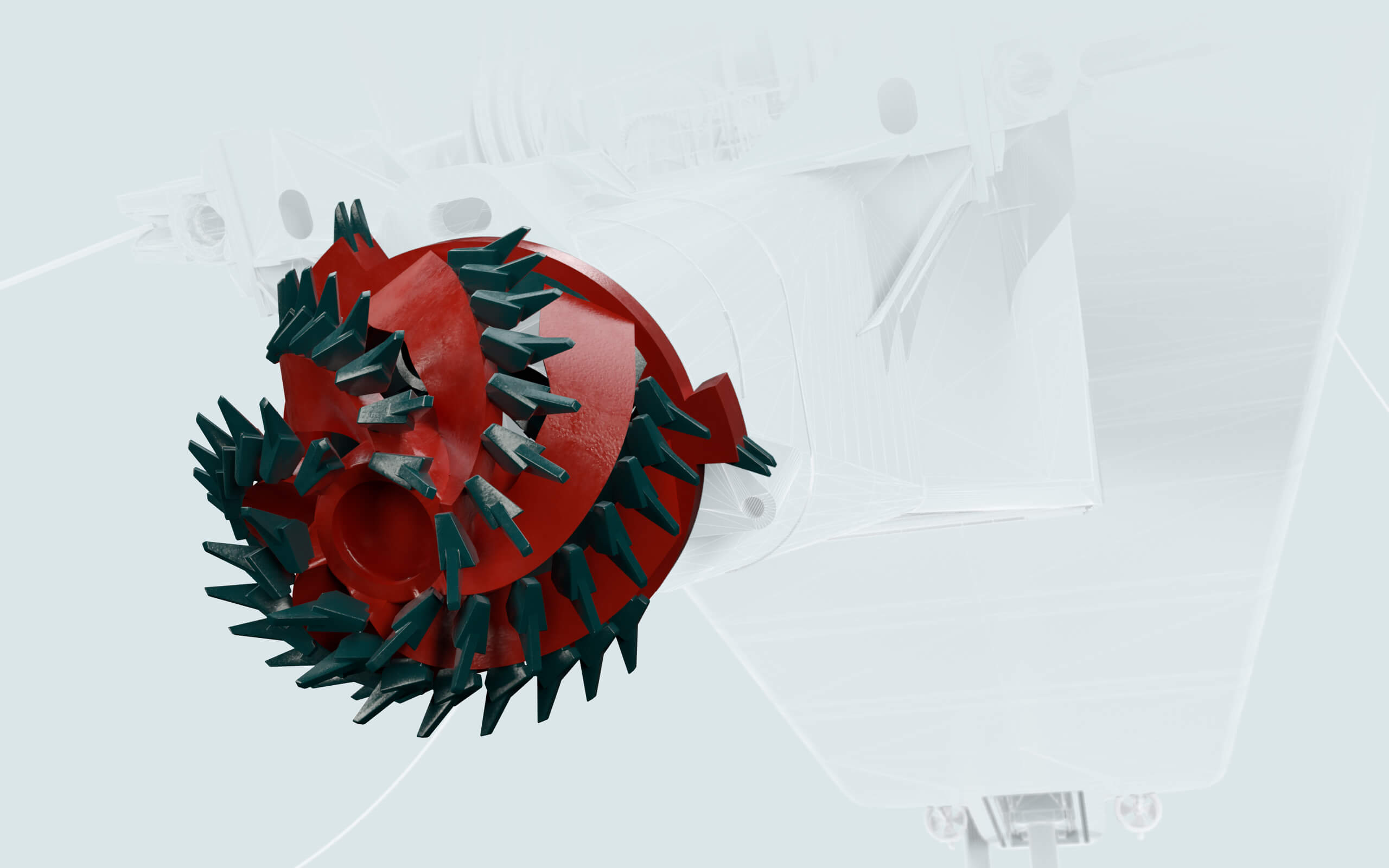

Inspired by DEME’s drive for innovation, our partner that specialises in pioneering cutterheads developed a completely new, more effective cutterteeth system. Spartacus has 14 cutterheads of 6 distinctly different designs that cover each soil type from fine sand to hard rock, meaning she always has the perfect tool for each soil type.

Get to know Spartacus

It is not all about power. Spartacus has many smart innovations on board, all of which make the vessel more capable, more efficient and more environmentally friendly.

-

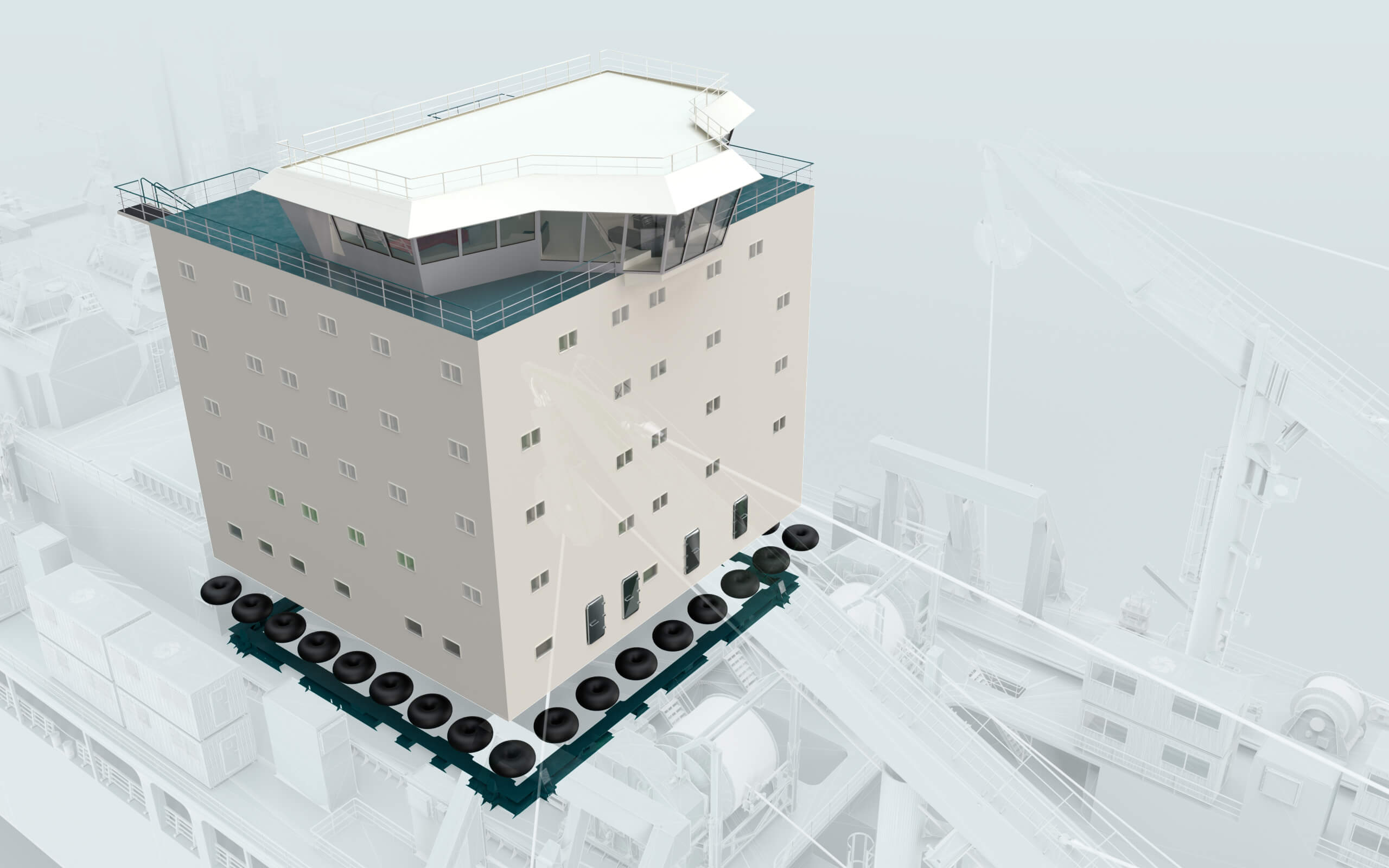

AccommodationTo provide extra comfort for our crews, the modern accommodation block, with a capacity for 72 people, is supported by air cushions.

-

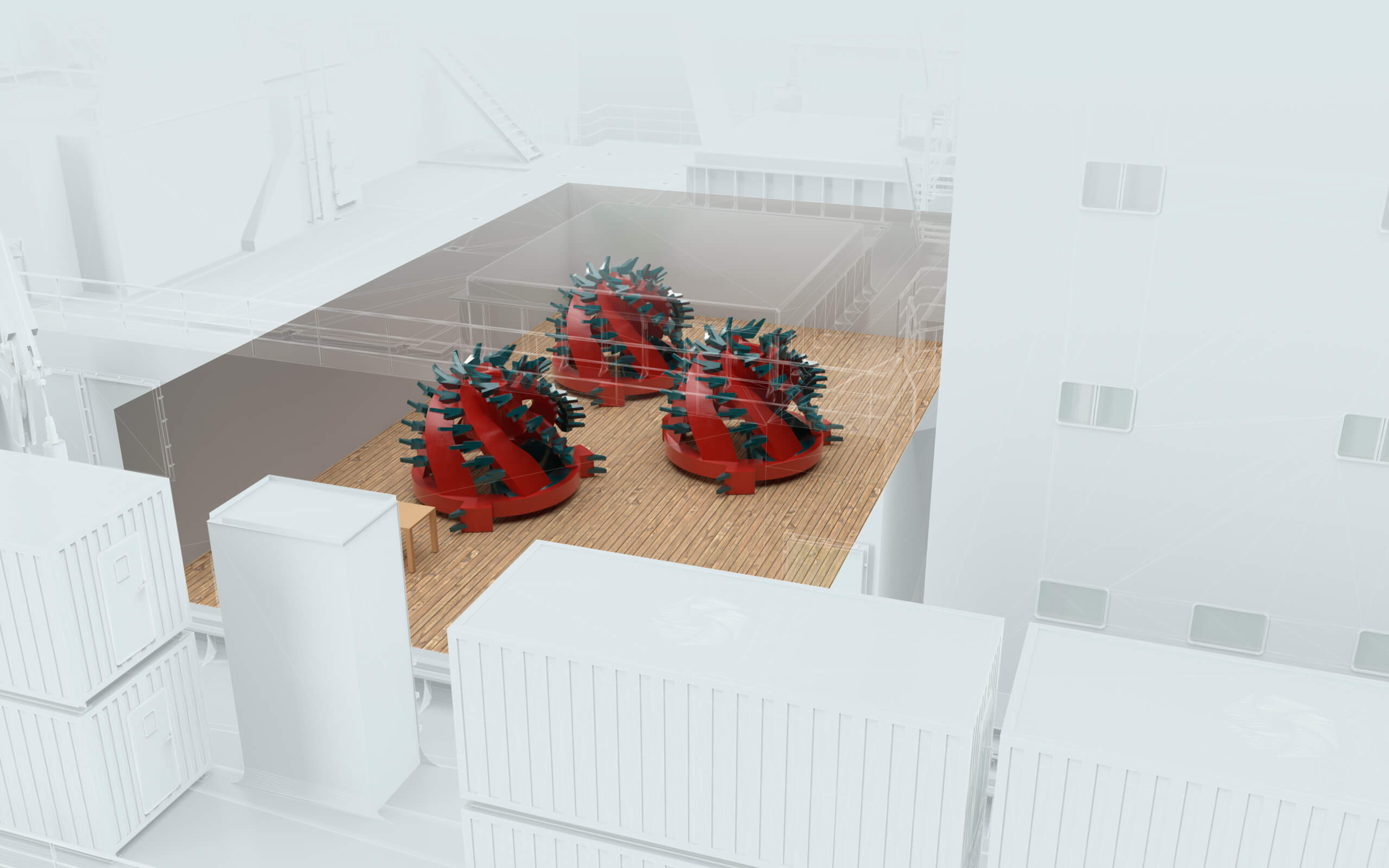

On board workshopThe on board workshop with a vibration-insulated floor makes it possible to carry out maintenance and repair of the cutterheads during operations.

-

Cutterhead14 heads of 6 distinctly different designs for a wide range of soil types, from fine sand to hard rock.

-

SpudsWith 72 metre long spuds, Spartacus can reach unprecedented depths of up to 45 metres. The working spud is held in DEME's patented flexible spud carrier which enables dredging in rough weather and challenging seas.

-

Cutter driveThe cutter drive delivers the necessary power (12,000 kW) to break new ground.

-

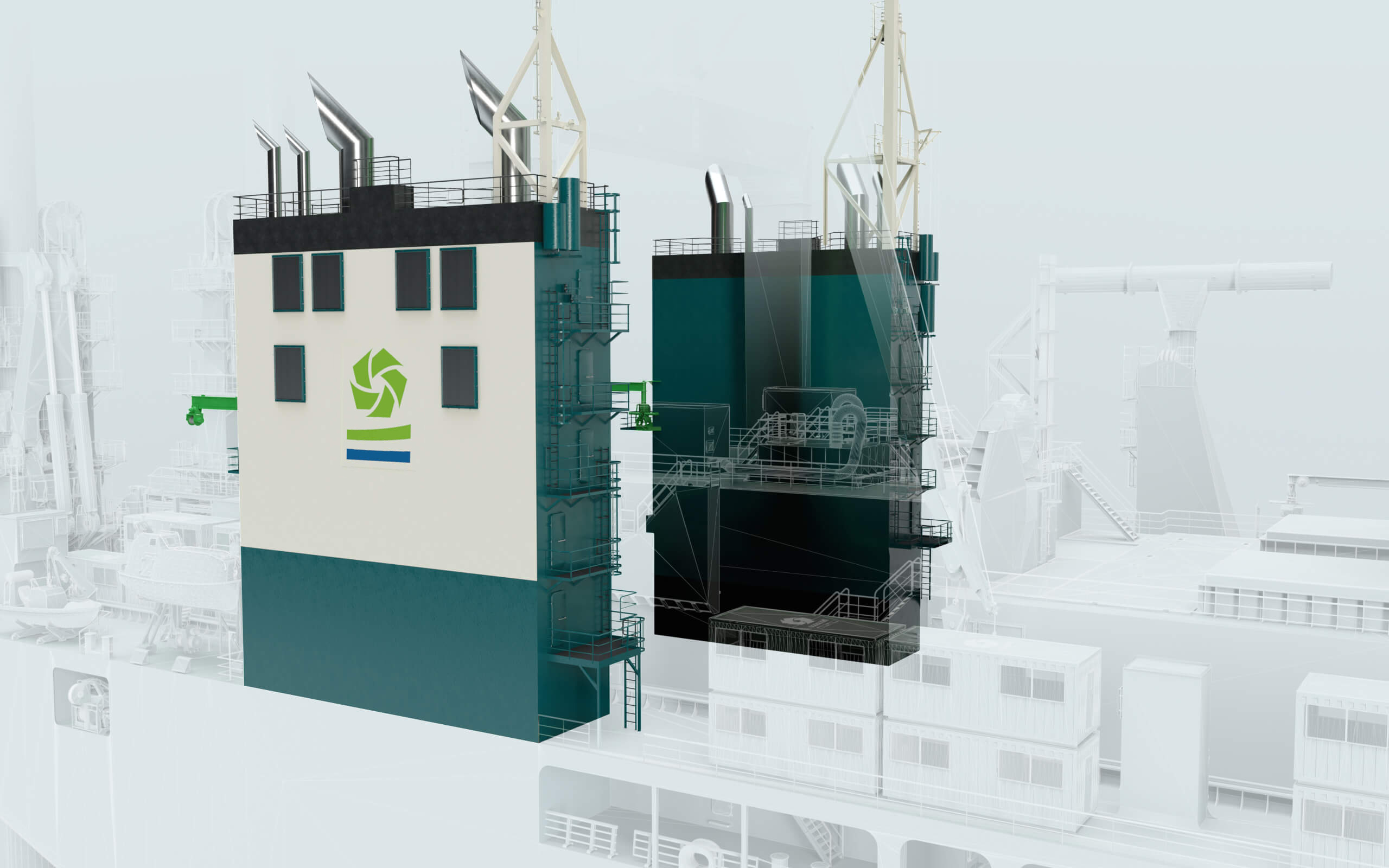

Triple fuelThis is the first cutter suction dredger in the world that can be powered by either LNG, Low Sulphur Heavy Fuel Oil or Marine Diesel.

-

44,180 kWtotal amount of power installed

-

164 mtotal length of the ship

-

-45 mmaximum dredging depth

-

+10 kmdistance Spartacus can pump dredging discharge

-

2,550 tonsweight of the ladder

-

7 mmaximum draught

Spartacus in numbers

Unrivalled uptime

We know that every break in production costs time and money. Which is why we designed Spartacus to keep going. And going. Raw power means nothing without the durability to match.

BUILT TO LAST

- Smart cutter ladder design focused on strength and material fatigue

- Vibration damper to absorb torsional vibrations of the cutter shaft

- Robust cutter gearbox design and smart cutter clutches

- Remote monitoring of critical equipment parameters to allow condition-based maintenance

SUPPORTING SPARTACUS

Such a mega cutter also needs the support of supersized barges. DEME has invested in two giant 3,500 m3 split barges ‘Bengel’ and ‘Deugniet’ to work alongside Spartacus and other large cutters and backhoes.

FAIR PLAY

TO PEOPLE

AND THE

ENVIRONMENT

Spartacus is one of the most powerful dredgers the world will ever see. Yet, looking beyond its power and ability to cut through the hardest materials, there is a soft spot for both people and the environment.

SAFETY BY DESIGN

The safety and comfort of our crew has been the single most priority. DEME raised the safety standards well beyond international requirements by analysing, documenting and preparing every single operation on board. Throughout this safety by design process, potential hazards were consistently eliminated, while efficiency and ergonomic gains were integrated throughout.

HIGHEST STANDARDS OF CREW COMFORT

During operations, the vibrations of a typical cutter suction dredger can make life on board quite a challenge. By installing giant air cushions underneath the accommodation, DEME has reduced vibrations by an impressive 80%.

OUR COMMITMENT TO SUSTAINABILITY

Making all of our operations environmentally-friendly and becoming climate neutral by 2050 is one of DEME’s most important strategic priorities. Firstly, we are investing heavily in fuel saving technologies and ways to do more with less fuel, and secondly, we are investing in the use of future fuels, with very low or zero greenhouse gas emissions.

TRIPLE FUEL FLEXIBILITY

All 6 engines can run on almost all fuels available today including LNG and biodiesel.

WASTE-ENERGY RECOVERY

Spartacus is designed to use energy as efficiently as possible. The air conditioning can be powered by cold recovery from LNG, while the heat from the main engine is converted into electrical power through a dedicated steam turbine.

A FUTURE-PROOF FLEET

With a versatile fleet of over 100 vessels, backed by a broad range of auxiliary equipment, we can provide solutions for even the most complex projects. We continue to strive for improvements in our productivity rates and environmental performance, and this is highlighted in our fleet investment programme.

Would you like more information on the world’s most powerful cutter suction dredger? Or do you need more information on our fleet?

Spotting

#Spartacus